Sample Results From Member Downloads

| Download Name | Date Added | Speed |

|---|---|---|

| Amada Ap100 | 13-Dec-2020 | 2,302 KB/s |

| Amada Ap100 Download | 13-Dec-2020 | 2,640 KB/s |

| Amada Ap100 KeyGen | 12-Dec-2020 | 2,101 KB/s |

| Amada Ap100 Unlock Key | 08-Dec-2020 | 2,629 KB/s |

| Amada_Ap100_Updated_2020 | 08-Dec-2020 | 2,739 KB/s |

| Amada.Ap100.Proper.rar | 05-Dec-2020 | 2,724 KB/s |

| Amada Ap100 (2020) Retail | 05-Dec-2020 | 2,420 KB/s |

Take advantage of our limited time offer and gain access to unlimited downloads for FREE! That's how much we trust our unbeatable service. This special offer gives you full member access to our downloads. Click to the Zedload tour today for more information and further details to see what we have to offer.

- AMADA software solutions are developed with the objective of increasing customer productivity. AMADA provides complete blanking, bending, tube, robot and welding software packs solutions.

- The software creates the bending sequence in manual of semi-automatic mode, giving the user the ability to determine the tools and machine configuration. Selection criteria are used to automatically select tools. The software relies on standard and special tools from the central tool library on the AP100 SDD server.

Many downloads like Amada Ap100 may also include a crack, serial number, unlock code or keygen (key generator). If this is the case then it is usually made available in the full download archive itself.

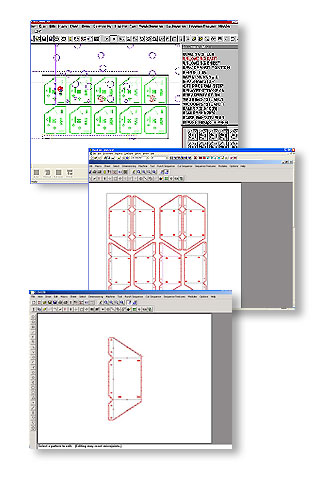

How to create common line cutting for FO in AP100 1. Use common line cutting function in AP100 then modify G code 1-1. Layout Parts in Sheet Process 1-2.

Akai Professional Download Drivers Free

Amada Ap100 Software Download

Design and Layout © 2020 Zedload. All rights reserved.

AP100 CAD allows you to quickly and efficiently design individual sheet metal components. In addition to the most common methods of 2D design, the software also offers 3D modeling and a selection of functions for sheet metal processing, which are implemented by the specific programming system of your software package.

The allocation of material and the application of suitable bend deduction data is accomplished by querying the AMADA database. All drawings of components are stored centrally in the AMADA database, so up-to-date data including potential changes to the component part can be called up at a moment's notice in all programming systems.

Naturally, it is also possible to import existing drawings of components in DXF/DWG format and adapt them for further processing or store them directly in the AMADA database. Tool drawings can be produced in AP100 CAD and managed in the AMADA database as special tool or mold. Punch and laser engravings can be added to sheet metal parts quickly and efficiently.